Vehicle repairs will always be uncomfortable. Even minor parts that should be replaced are a hassle simply because they siphon away your short time. Whenever your fuel filter, catalytic ripper tools, or alternator fail, the knowledge becomes much less enjoyable. Furthermore individuals components are more expensive, however the labor involved with replacing them can also add 100’s of dollars towards the final bill. Because of this , mechanics will frequently ask whether you need the failing components substituted for reconstructed, remanufactured, or used auto parts.

You will find benefits and drawbacks to every. Below, I’ll explain what each option offers as well as their particular drawbacks. I’ll then explain why OEM (Original Equipment Manufacturer) certified parts will be the best option.

Exactly What Does “Reconstructed” Mean?

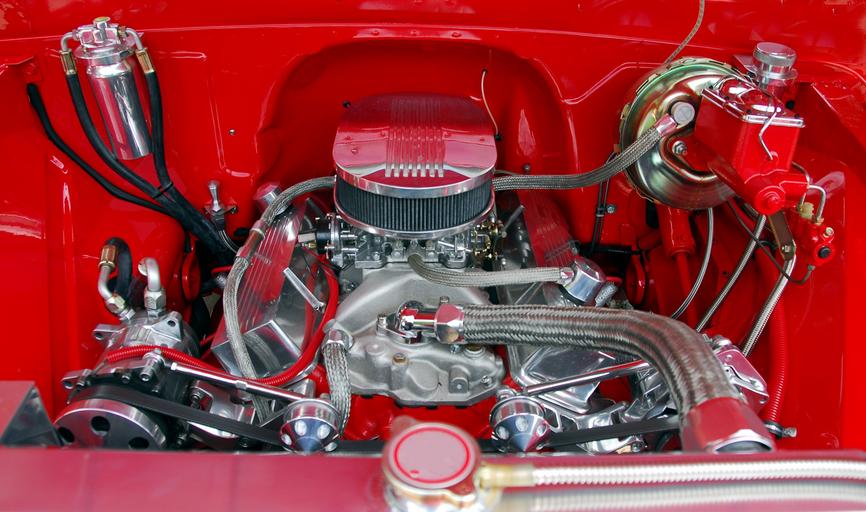

Parts which are reconstructed are a mix of original pieces and individuals which have been accustomed to replace failing pieces. For instance, suppose your alternator shows indications of failing. It’s really comprised of multiple individual pieces, including several terminals, a current regulator, along with a diode rectifier. Failing may be as a result of single piece. If that is the situation, you could have the auto technician simply switch the individual piece that unsuccessful to obtain your vehicle back on the highway.

Sometimes, mechanics uses a core. This occurs once the failing component out of your vehicle is worn to the stage it can’t be reconstructed. The main is obtained from another vehicle and also the bad pieces are replaced.

Among the drawbacks to reconstructed vehicle parts would be that the substitute pieces is going to be new while all of those other component may have experienced some deterioration. The disparity could possibly introduce heat stress along with other problems. Furthermore, the initial alternator (within our example) can always fail soon.